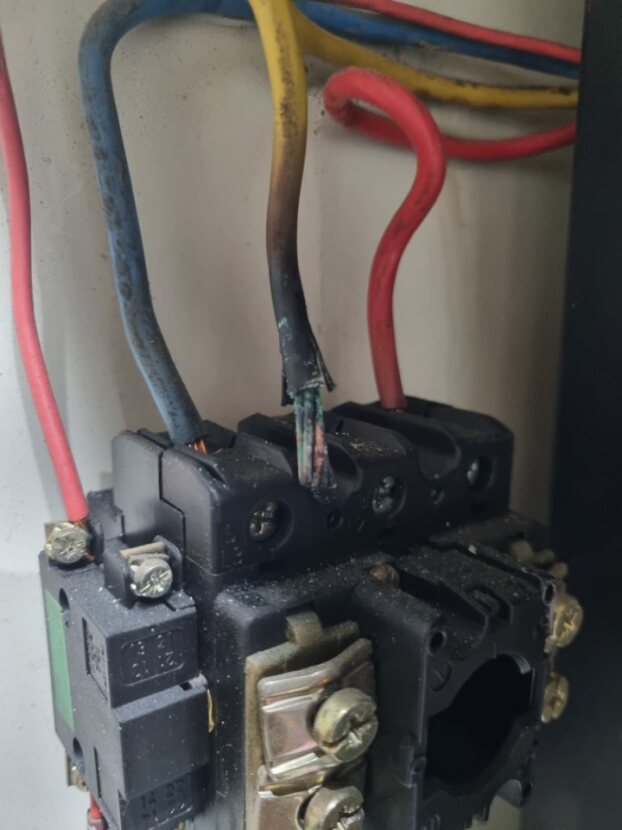

What’s black, yellow, and hot…? This middle cable! But this is no joke…

On a recent inspection by our team conducting testing in a control panel for a large industrial 63 AMP Three Phase Oven, this cable was found not terminated correctly into the terminal. This therefore over time, caused heat build-up and potential arcing within the terminal, which had led to the thermal damage.

The Yellow/L2 phase supply conductor to the panel, was originally behind a clear, Perspex protective casing, going into the supply side of the main rotary isolator. This hid most of the damage, showing only a slight bit of charring on the cable. Initially, the terminal of the isolator was tight, with test results not identifying any issue, however on closer inspection once the Perspex cover was removed, the cable itself was not terminated correctly into the terminal. Highlighting the importance of on-site regular inspection from our Guardian team.

So, the Guardian team made the client aware, and the issue was rectified, tested, and checked again. It was left in satisfactory condition with a happy client.

Do you regularly undertake fixed wire inspection and testing programmes using thermographic imaging? We can make this simple for you:

📞 0114 257 2080